Polyurethane Bulk Storage and Blending Systems

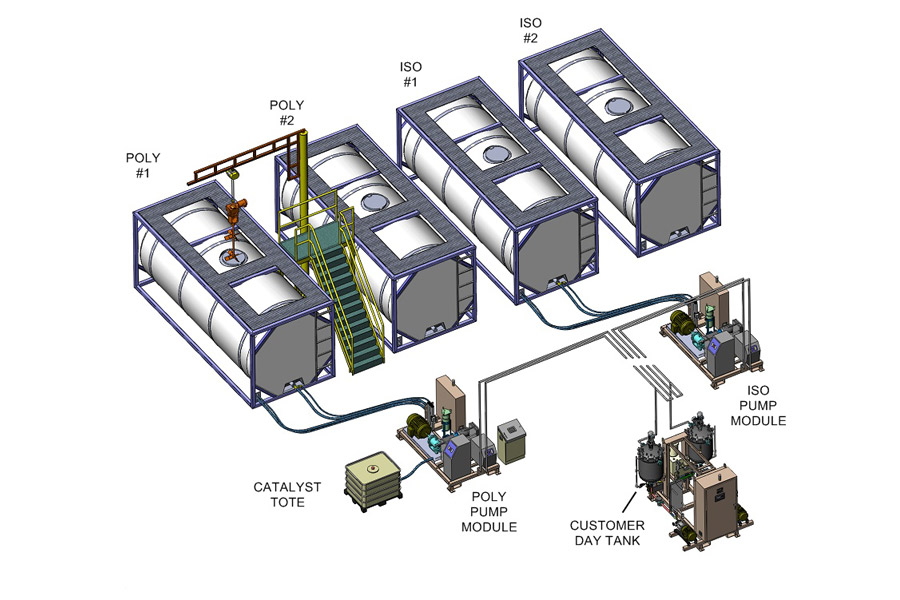

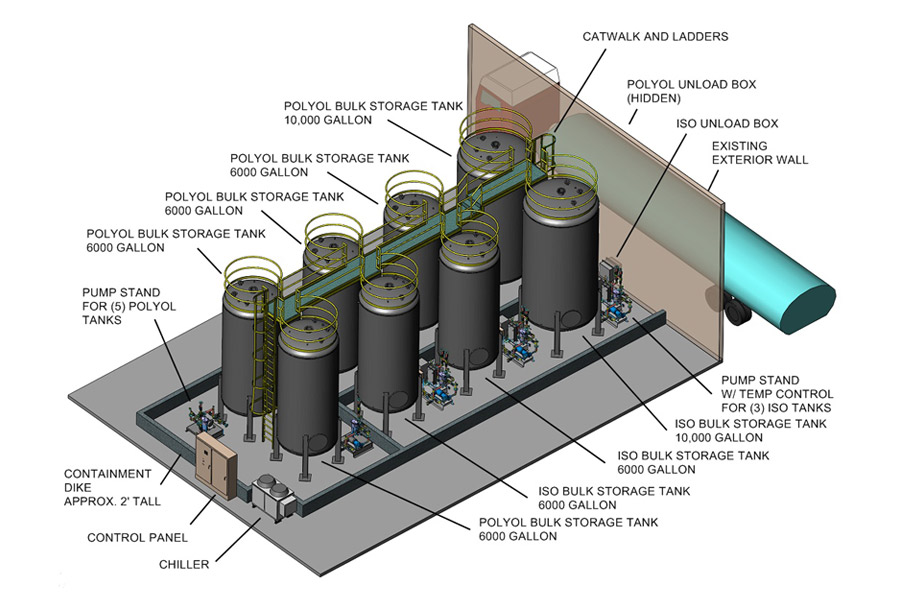

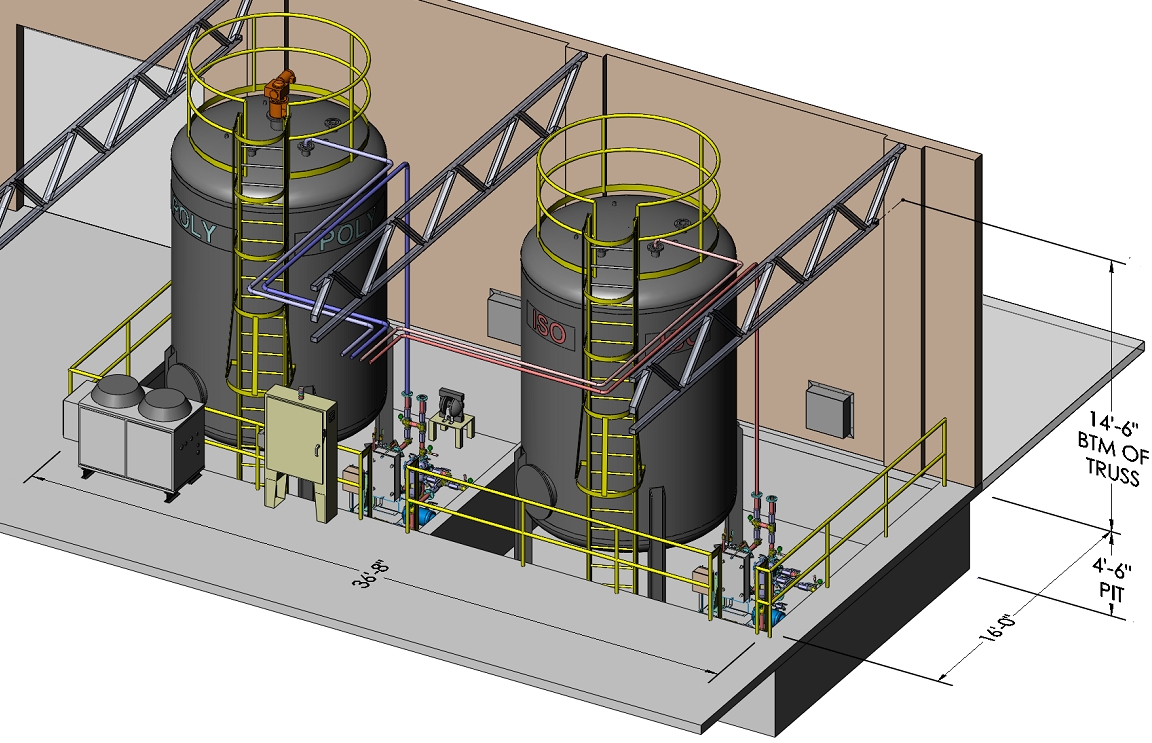

Polyurethane Bulk Storage Systems

As your organization grows or your production demands increase, the need for more material logically increases as well. To ensure you’re able to meet your production demands while also reducing material costs and other expenses associated with increased production demands, Linden Polyurethane can partner with you on customized, efficient chemical bulk storage systems designed to meet your production requirements as well as your building constraints.

We are proud to have worked with numerous companies around the world for their bulk storage needs. From 2000-gallon bulk storage systems for deliveries from split tank trucks to 25000-gallon railcar tank deliveries, Linden Polyurethane will work with you to design a custom storage system that keeps you producing more while realizing significant cost savings on bulk material orders. We can also work with you on a bulk storage systems for environmentally friendly Cyclo-Pentane, or HFO.

Highlights

- Bulk chemical storage sizes from 2000 to 25000 gallons

- Cyclo-Pentane bulk storage systems up to 6000 gallons

- All tanks custom-designed to meet your building restrictions

- Supplied in carbon steel with plasite lining or stainless steel

- Engineering at the highest quality with ASME-certification

- Can be engineered to comply with CRN Registration

- Can be coupled with Linden Polyurethane bulk blending systems

- Supported by a best-in-class warranty and repair program

Polyurethane Blending Systems

In addition to partnering with you on a more productive- and cost-friendly bulk storage system, Linden Polyurethane can also support your organization with efficient chemical blending system. These blending systems are custom-designed to your specific production requirements and can be set up in-line with our bulk storage tanks. This ensures that material is seamlessly processed from the moment it is delivered to your facility to the moment it’s ready to be dispensed. Ultimately, this saves your organization significant time and resources in managing your chemical blending and processing needs so you can spend more time focusing on the application at hand.

Highlights

- In-line polyol, filler/color, and blowing agent blending systems available

- Penta-Fusion and environmentally friendly blending (EFB) systems available

- Filler blending and handling system ensures cleanliness and reduced material loss

- Seamless integration with polyurethane bulk storage systems

- Supported by a best-in-class warranty and repair program

Ready to Get Started?

Please contact us to discuss specifications for this equipment.