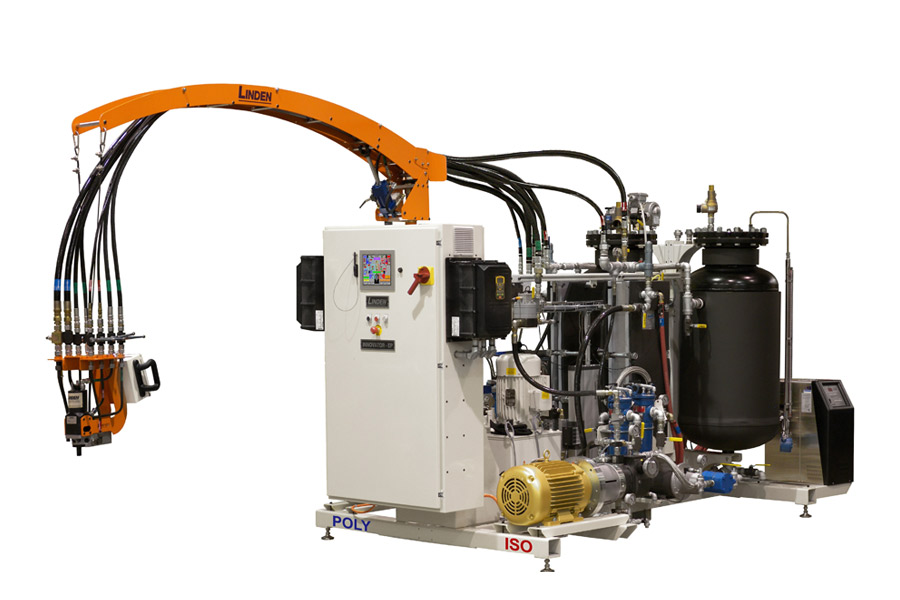

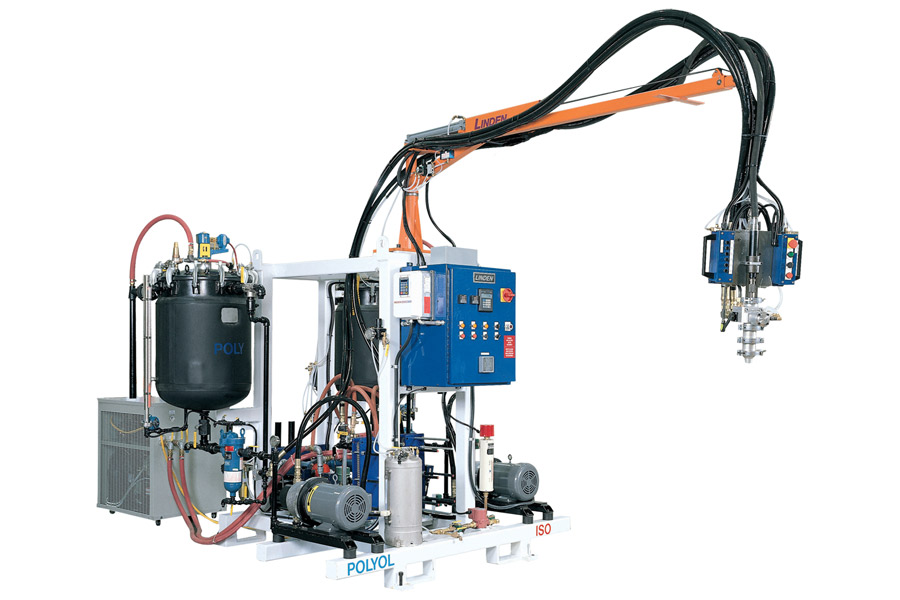

Polyurethane Mixing and Dispensing Equipment

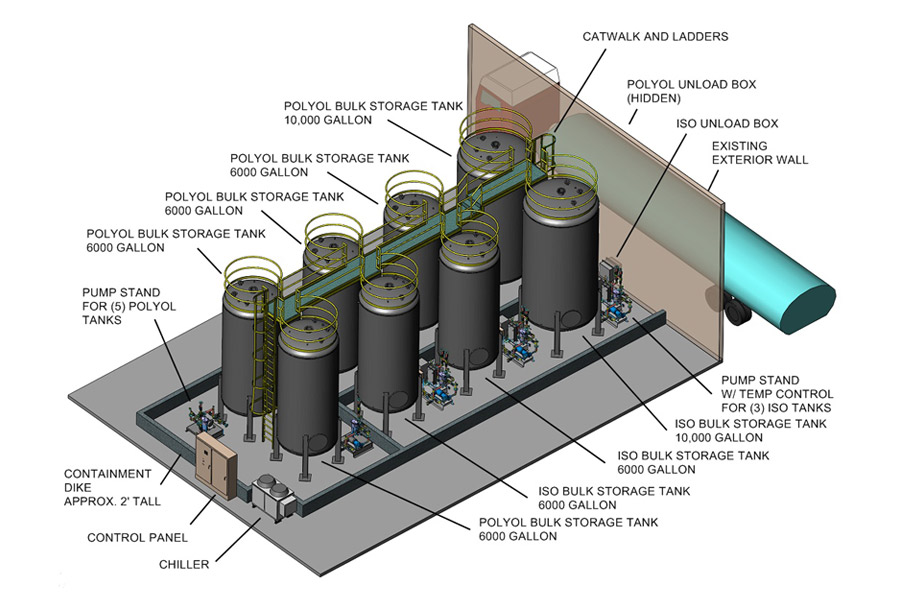

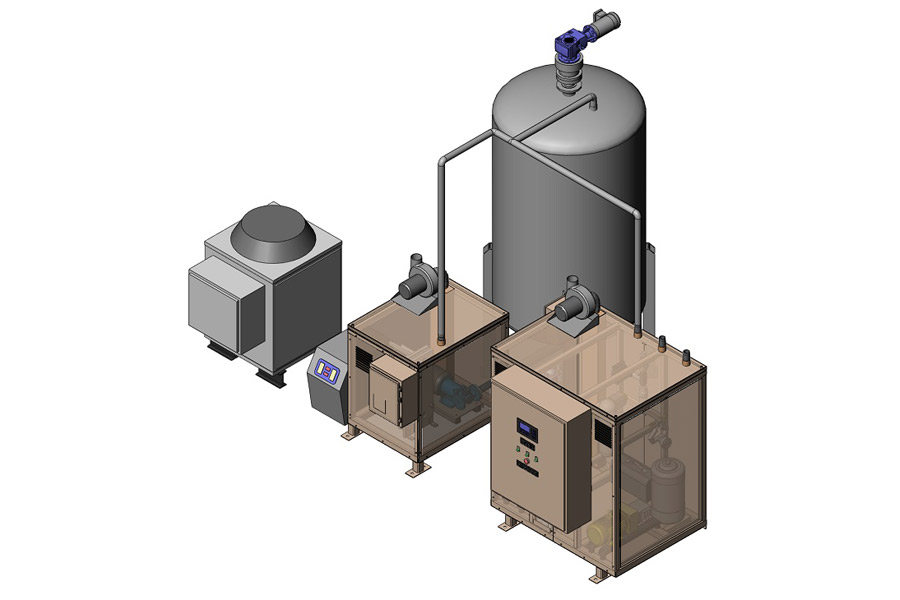

Linden Polyurethane designs, manufactures, and supports polyurethane mixing and dispensing equipment for industries and organizations around the world. We offer a variety of mix heads, metering machines, bulk storage, nucleation, blending, and more.

For more than 35 years, Linden Polyurethane has served as a leading partner in the global polyurethane industry. As the only full service U.S.-based polyurethane mixing and dispensing equipment manufacturer, Linden Polyurethane engineers a broad portfolio of high-pressure metering systems, spray machines, bulk, blending and storage systems, pentane, and gas infusion equipment and systems. We support and specialize in critical applications in the aerospace, medical, and military industries as well as in construction, sporting goods, automotive, and appliances.

Each order entrusted to us is custom-designed, manufactured, assembled, and serviced at our global headquarters in Cuyahoga Falls, Ohio. We are application-driven in everything we do, meaning we tailor your solution specifically for your unique processing needs to ensure you’re able to meet production goals as quickly and efficiently as possible.

Our polyurethane processing equipment is available in a variety of configurations and outputs, with metering systems capable of shot sizes ranging from a low output of 3g/sec to a high output of 3.6kg/sec and processing capabilities of up to 2900 PSI. We also provide industry-leading auxiliary equipment focused on helping your organization achieve increased up-time and reduced material and operations costs.

As the only full service U.S.-based polyurethane equipment manufacturer, Linden Polyurethane is the market leader in repair services and in-house testing. We provide service and parts for our custom-designed polyurethane mixing and dispensing equipment as well as for those manufactured by other organizations. Our services are offered at competitive prices with rapid turnaround times, ensuring as little interruption as possible. We are also able to provide remote monitoring and diagnosis to further support your equipment. Learn more about our support here. If you are in need to conduct a low-volume process run or would like to do some testing, Linden Polyurethane has a world class facility to accommodate your needs. Learn more about our test lab here.

Explore our polyurethane mixing and dispensing equipment capabilities below. Remember that we can support virtually any custom application or equipment need your organization may have. If the solutions below won’t address your polyurethane mixing and dispensing equipment needs, contact us to discuss your specific solution and how we may be able to help. Our team will work closely with you to ensure that your custom polyurethane processing goals are met.