Polyurethane Mix Heads

Polyurethane mix heads are where the final output of your engineering, hard work, and vision becomes a reality. That’s why it’s critical to use polyurethane mix heads that are precision crafted with over 35+ years of experience.

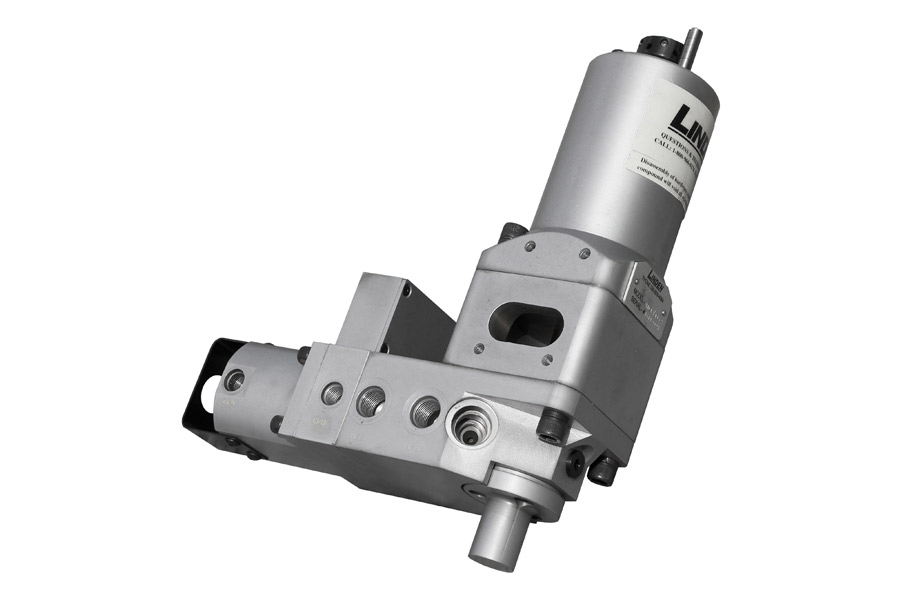

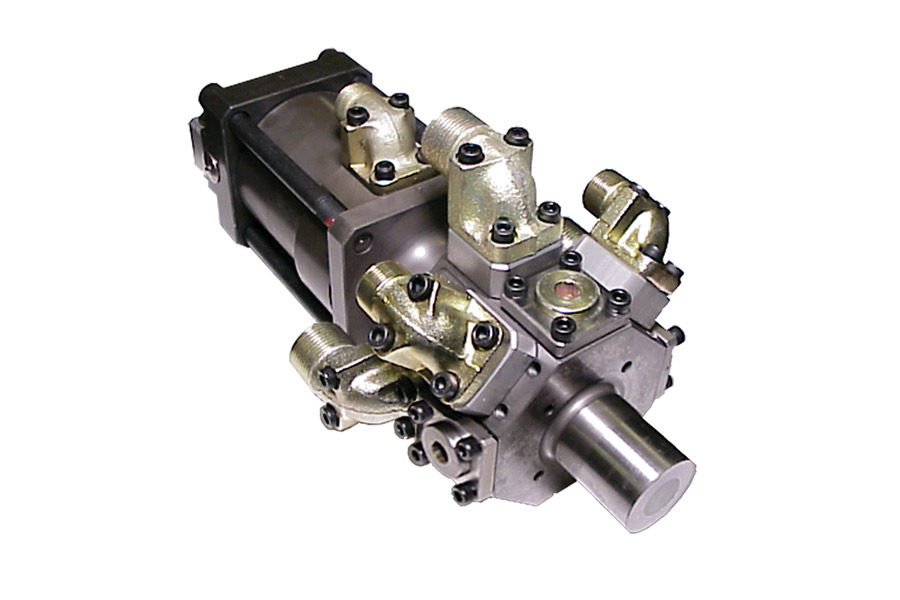

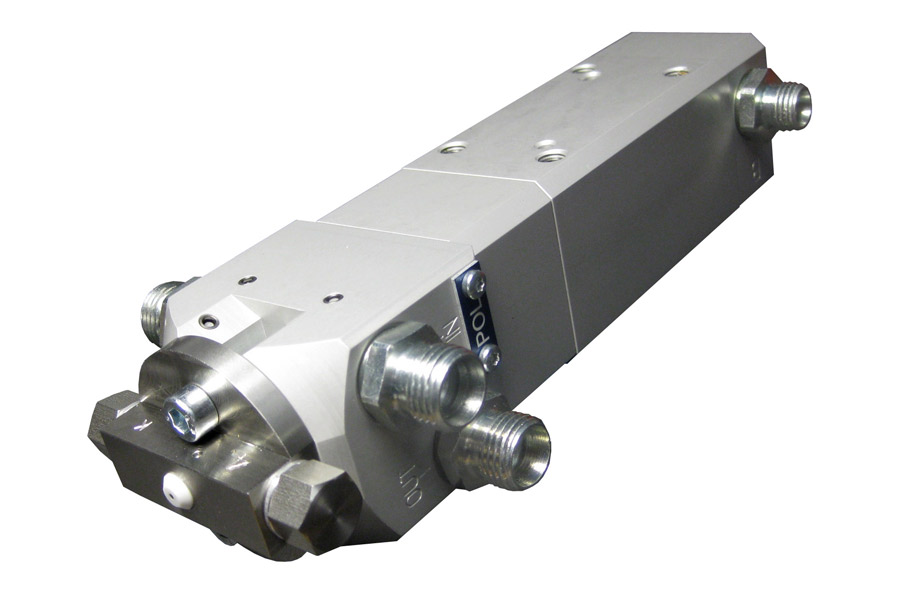

Since we began operations in 1985, Linden Polyurethane has been designing, engineering, testing, manufacturing, and servicing only the best in polyurethane mix heads. While we offer a variety of mix heads with varying capability and features, every single mix head that we produce is aligned with our customers’ exact specifications and needs. Whether you’re using Linden Polyurethane equipment or machines produced by other organizations, we evaluate your goals to best match you with the best suited mix head to achieve them.

Our mission has been to offer the highest quality, most reliable, and efficient high pressure reaction injection molding (RIM) mix heads to the global polyurethane market. Linden Polyurethane offers new replacement mix heads for popular manufacturers such as: Cannon, Hennecke, Krauss Maffei (KM), and Elastogram (EMB).

But precision and reliability aren’t our only focus. In fact, Linden Polyurethane has been at the forefront of many mix head innovations. For example, Linden Polyurethane was the first to offer mix heads equipped with a built-in electronic shot counter — a key component of both the device and our best-in-class warranty. Recently, we had a mix head returned for a clean and seal with more than 10 million cycles on the shot counter!

When you work with Linden for your next mix head need, you not only receive top-of-the-line design and functionality, but you also receive service and support that cannot be beat. We offer a complete repair and part replacement team that can support your operations now and for the long-term. We even service polyurethane mix heads designed and built by other industry organizations. We can monitor your existing operations remotely thanks to our advanced technology and work with you on troubleshooting and any other support needs you might have.

And because Linden Polyurethane is the only full service U.S.-based polyurethane equipment manufacturer, we have the unique ability to not only provide premium machines and parts but also to service them quickly. Learn more about our rebuild, repair, and part replacement programs as well as mix heads that can be loaned out while yours are in service.

Finally, Linden Polyurethane understands the importance of efficiency and speed — especially when it comes to maintaining your production schedule and capabilities. That’s why we stock inventory on mix heads and semi-finished components so we can quickly ship out new mix heads — whether they’re being purchased new or serve as a temporary solution until a new mix head is ready or existing mix head has been repaired.

Explore our mix heads offerings below. Don’t hesitate to contact our expert team if you have any questions about our mix head capabilities and services. We would be glad to assist you and identify a solution to meet your needs.