Why Polyurethane Foam Cell Structure Matters

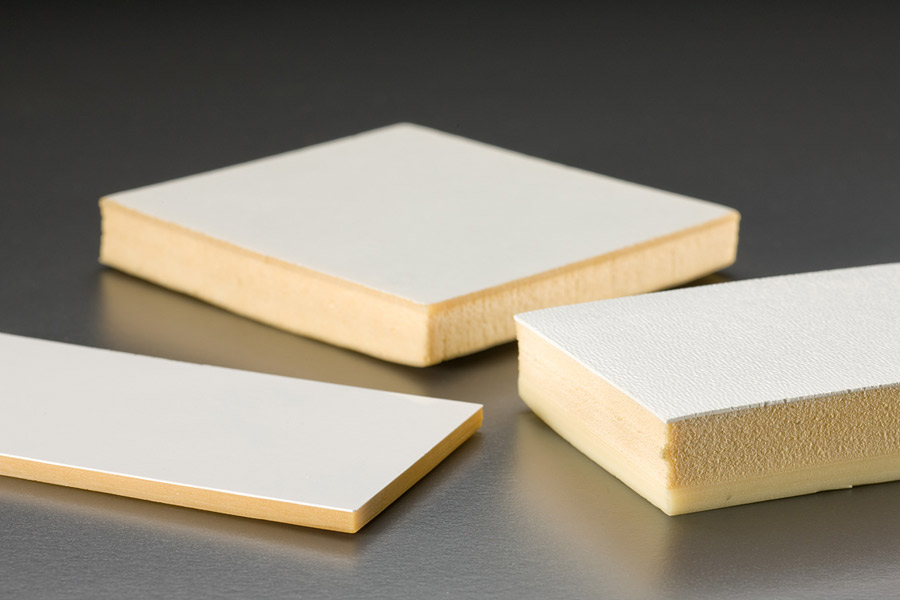

Polyurethane foam cell structure is critical to multiple industries for countless products that consumers and businesses use each and every day. Many of these products are part of our daily activities, but just as many — if not more — go unseen. That’s because they serve as a structural, protective, or other foundational element of those products.

For example, polyurethane plays an important role in the automotive industry. In addition to serving as the structural core of many parts ranging from seat cushions to bumpers, polyurethane also protects passengers from excess noise. The industry also uses polyurethane because it’s vastly lighter than other materials used in the structure of vehicles. Polyurethane foam cell structure is thus incredibly important to automotive manufacturing companies.

But it’s important to remember that polyurethane is a mixture — a combination of two chemical materials with varying ratios to achieve different attributes. And the way that mixture is produced makes a direct impact on polyurethane foam cell structure and the resulting performance of that foam.

To support the mixing process and ensure the resulting material achieves the performance properties desired as well as high levels of production quality, gas nucleation is used to enhance the polyurethane foam cell structure. Gas nucleation is the process of dissolving and distributing a gas into a polyurethane mixture.

Types of Gas Nucleation

CO2 for Material Properties

Carbon dioxide can be introduced into a polyurethane mixture to achieve certain qualities. For example, when added to the polyol component of a urethane mixture, CO2 helps to reduce overall part weight as well as material usage. This enables companies utilizing polyurethane in their production process to realize significant cost savings as well as improved levels of performance from the final product. CO2 also helps to improve sound absorption — a beneficial feature that is in use in countless industries across the world.

How Linden Polyurethane Can Help

Linden Polyurethane offers CO2 gas infusion equipment to help companies achieve the properties they’re looking for in their polyurethane production as well as key business results such as cost and material reduction. Our CO2 gas blending system continually monitors and updates the level of CO2 in a polyurethane mixture, making adjustments as needed to ensure only the most homogenous mixture. Learn more about our CO2 blending system here.

N2 for Production Quality

Through the use of advanced mix heads, polyurethane foam can be dispensed into a variety of open and closed molds as well as sprayed for various applications. Because of this, it can be extremely difficult to maintain consistent levels of quality. It can also be difficult to fill complex geometries where material may have difficulty flowing. Material flow itself can also be challenging for certain mixtures. By introducing Nitrogen into the mixture, the polyurethane foam cell structure can remain free from surface defects, dispense more evenly, and improve mixing quality — among many other benefits.

How Linden Polyurethane Can Help

By continuously introducing N2 into the mixture, companies can realize a number of specific benefits. These include better wet-ability, mixing quality, and surface quality. Thanks to N2 infusion, material dispensed on a surface that would otherwise streak, run, or not fill (like a wall) receives a stronger, higher-performing material distribution. And of course, because of the improved performance, companies also reduce the number of scrapped parts as well as their landfill costs. Our N2 infusion system can be customized to your specific polyurethane foam cell structure goals. Learn more about the system here.

Ensure the Quality of Your Polyurethane Foam Cell Structure

Polyurethane is an amazing material, but with gas nucleation and blending equipment, its already numerous benefits become even more plentiful. At Linden Polyurethane, we’re leading the way toward better polyurethane production with custom-engineered gas nucleation equipment that produces only the best polyurethane foam cell structures and business results. Contact us today to learn more about our gas nucleation equipment.