Match Your Application with the Right System

In multiple industries, the material used in products, structures, and components makes all the difference when it comes to performance. The different choices when it comes to selecting a polyurethane foam mixing head have the same effect.

Different grades of steel are needed for moisture- and chemical-resistant applications versus steel needed for extreme toughness and wear resistance. Rubber formulations depend on the temperature requirements and chemical features of an application.

The same goes with polyurethane — the application performance parameters will determine the chemical mixture. A number of systems work together to create this mixture, such as bulk storage and blending systems, high- or low-pressure metering systems, and gas nucleation equipment. But perhaps the most important of these is the polyurethane foam mixing head (also just called a mix head).

The polyurethane foam mixing head does exactly what it sounds like: it mixes the chemicals supplied to it from a previous system and then distributes the resulting blend according to the application. This might include open or closed pouring, spraying, or some other distribution method. And while this sounds like a straightforward process, there are a number of details that must be considered to ensure you’re using the right tool for your production needs.

Precision and consistency: Learn more about what goes into the right polyurethane mix head, and how Linden has been excelling in equipment design for nearly 40 years.

4 Polyurethane Foam Mixing Head Systems with Examples

L-Style Mix Heads

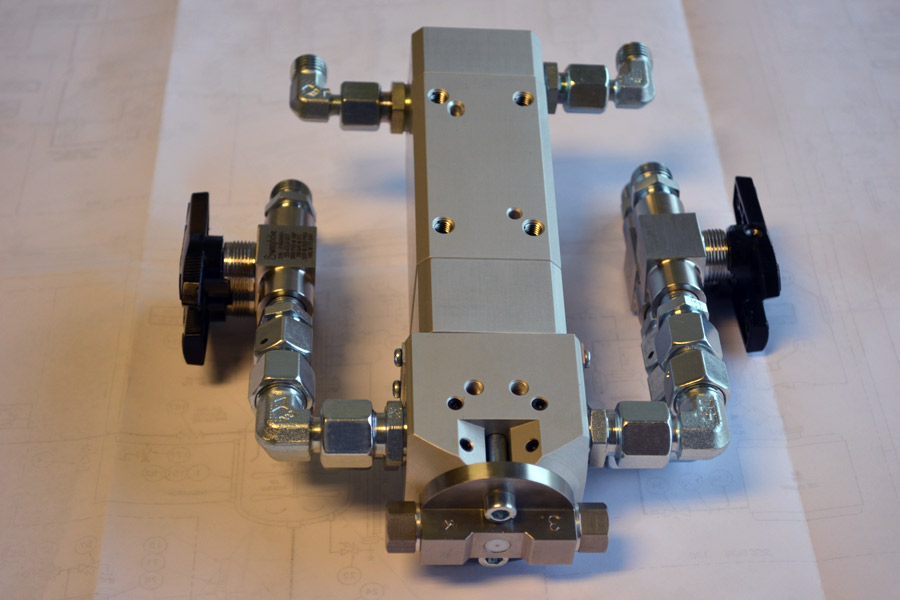

L-style mix heads are advanced systems that utilize simple yet effective geometry to create highly effective chemical mixtures and output options. Just as it sounds, an L-style mix head features two mixing chambers arranged perpendicular to one another. Chemicals counter-impinge in a small cylindrical chamber, followed by a 90º angle for more thorough mixing that also helps to slow the chemical velocity and ensure a more steady flow. After the chemicals mix, they are distributed.

Linden L-Style Mix Head

- Available in 2- and 3-stream and duplex variations

- Ideal for molded, flexible, and rigid foams as well as filled systems

- Mix ratios ranging from 1:1 to 3:1 to support your chemical mixing needs

- Splash-free pouring ensures your surface finish remains flawless

- Features an electric shot counter and advanced self-cleaning system

- Comes in a compact and user-friendly design for ease of use

Linden-Isotherm GP 600™

- Ideal for applications requiring a smaller output

- Supports incredible small shot sizes — only 3 grams!

- Mix ratios ranging from 1:4 to 4:1 using different chambers

- Features a modular design for customization

- Splash-free pouring into open or closed molds

- Metal-to-metal sealing ensures lasting reliability

Straight-Style Mix Heads

Whereas L-style mix heads are ideal for higher-pressure applications, straight-style mix heads are ideal for closed-pouring applications that require longer nose lengths in order to reach the tooling. They are precision-engineered, just as with any other polyurethane foam mixing head, and feature specialized surface treatments on critical components to ensure they continue to perform reliably for years to come with minimal maintenance. And just like L-style mix heads, they feature an electronic shot counter for maintenance purposes.

Linden Straight-Style Mix Heads

- Available with three different nose lengths depending on your application

- Streamlines productivity by enabling pouring in hard-to-reach locations

- Available with two to four streams to support your mixing needs

- When not pouring, chemicals are recirculated to maintain temperature and proper ratios

- A precision-machined plunger for self-cleaning removes leftover material

Spray-Style Mix Heads

Unlike L-style or straight-style mix heads that mix chemicals in chambers and then distribute them into molds or via flows, spray-style mix heads are meant to do exactly what they say — spray! They distribute the material at high pressure onto a surface or part, such as with coatings or building insulation, with the chemicals being delivered to the mix head via heated hoses that ensure the material performs as desired.

Linden–Isotherm Spray-Style Mix Heads

- Available with circulating or non-circulating capability

- Available with hydraulic, pneumatic, or manual actuation

- Mounted via robotics or manipulators or used as a hand-held sprayer

- No solvents or flushing is needed as the system mechanically self-cleans

Find the Right Polyurethane Mix Head for Your Goals

Linden Polyurethane has been designing, engineering, manufacturing, and servicing polyurethane foam mixing heads for nearly 40 years. Every system we produce is precision-engineered using only the best materials and components. Nothing is off the shelf — each system is manufactured according to the specifications that will support your production goals now and for the long term.

In addition to our renowned manufacturing capability, we also service, test, and repair mix heads — ours and those of our competitors. We can troubleshoot your systems remotely thanks to our technology solutions, dispatch field technicians to your location, and conduct equipment and application testing in our 7,000-square-foot testing and production facility.

If your polyurethane foam mixing heads need to be sent into our facility, we offer repair services to bring them back up to peak performance rapidly. Our rebuild services enable existing mix heads to be stripped down, cleaned, and updated with high-performing parts and components, giving them added life and maximizing your investment before having to make another purchase. We even offer mix head rentals while your primary mix head is in our shop for service.

If you’re looking for a new mix head, need to identify a solution for a future product, or want to validate a mix head choice, Linden Polyurethane is here to support your success.