Core Production Elements Add Value and Versatility

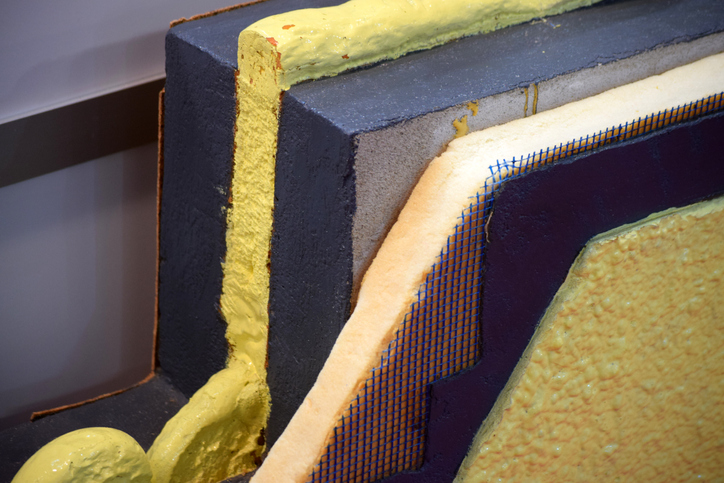

Polyurethane foam uses the same core elements to serve as the building blocks for a material that has applications across virtually every industry and runs the gamut from essential insulating material for the latest aircraft to the filling of cushions on your couch.

Polyurethane foam comes in two distinct, if still widely encompassing, categories — flexible polyurethane foam and rigid polyurethane foam. Both have six main components, including the polyols and diisocyanates which are the principal elements of all polyurethane products. With the addition of blowing agents, surfactants, and catalysts, polyurethane foam can take on a wide array of different characteristics.

These are evident in the polyurethane foam uses seen across many markets. Flexible foam is widely used as a mattress material and cushioning for furniture and car seats. Rigid foam is a mainstay in construction, serves as an insulator for aircraft, and plays a part in boat and shipbuilding.

There are many more polyurethane foam uses. Appliances use rigid foam for thermal insulation to enable refrigerators and freezers to do their jobs. The ability to reduce the weight of components, without sacrificing strength, has led to myriad foam uses in military applications. Sports equipment, from the construction of helmets to pads and shoes, has long used polyurethane foam.

Versatile and adaptable, polyurethane foam relies on the various components used in its production to augment and toggle some of the characteristics that allow it to find a place in so many products and markets. Today we’ll examine three of these core production elements.

Get More from Your Chemical Mixture: Examine the difference a gas nucleation system can add to your production, through efficiency, additional properties, and more.

Enhance Performance and Quality of Polyurethane Foam with the Right Equipment

As demonstrated above, polyurethane foam uses include applications across virtually every industry and sector imaginable. But guaranteeing the best quality of polyurethane foam — and application performance — rests on optimizing the various components of your production environment. Three core elements of this environment are metering, gas nucleation, and mix heads.

Metering

Polyurethane metering systems are the starting point for polyurethane foam production. These systems reside at the center of the entire process and are vital to achieving the right material balance and distribution rate for your application.

Polyurethane foam uses metering systems in two broad types. High-pressure metering systems excel in applications that require a high volume, or for low-output situations involving open or closed mold pourings. Meanwhile, low-pressure metering systems excel when the application uses lower volumes, other non-polyurethane chemicals, or a mixture with varying or higher viscosities.

For the best results, you’ll want properly designed and engineered systems tailored specifically to your application. For instance, you’ll most often engage low-pressure metering systems for polyurethane foam uses centered on insulation in the construction and automotive industries.

View the Linden-Isotherm PSM 90 datasheet (high-pressure)

View the INNOVATOR EP datasheet (high-pressure)

View the Polytec/Linden DG 132 datasheet (low-pressure)

View the Polytec/Linden DG 200 datasheet (low-pressure)

Gas Nucleation

The performance of the polyurethane foam can be enhanced further, or additional characteristics imbued, with the use of this process — which typically adds carbon dioxide (CO2), dry air, or DiNitrogen (N2) to the mixture. Gas nucleation equipment can make the end material lighter (as with CO2), or improve the consistency of the mixing quality and/or improve the overall cell geometry (dry air). Both help ensure the resulting polyurethane application will achieve the desired results while reducing the risk of material failure.

Lighter polyurethane foam produces the strength needed without additional weight — for example, naval vessels often incorporate forms for buoyancy while also adding sound-damping qualities. Improved mixing quality means eliminating voids and greater cell geometry ensures uniformity throughout the material and eliminates some of the inability of the material to remain consistent once dispersed. Failure to produce a reliable geometry results in a damaged product that needs to be scrapped, thereby increasing cost and production time.

View the CO2 Gas Infusion(™) unit datasheet

View the Dry Air/N2 Gas Infusion(™) unit datasheet

High-Performance Mix Heads

As one of the last pieces in the production process, mix heads provide one last opportunity to increase the performance of your mixture, application, and product. How the polyurethane foam material is mixed in this step will impact performance.

The mixing head does exactly what it says: it mixes the chemicals supplied to it from other systems and distributes the blend according to the application. This might be spraying, open or closed pouring, or some other distribution method. Mix heads come in a variety of styles — including L-Style, Straight-Style, and Spray-Style varieties. Each contains a multitude of details that must be considered to ensure the right tool for your specific production needs is being used.

Go In-Depth with Mix Head Options: Match your application with the right selection from our line of mix heads for greater efficiency and performance.

Cover All Your Polyurethane Foam Uses with Linden Polyurethane

For nearly 40 years, Linden Polyurethane has designed, engineered, and manufactured the equipment needed for the production of polyurethane and for adding desired properties to the versatile material. Our broad portfolio of metering systems, spray machines, bulk, blending and storage systems, pentane, and gas infusion equipment and systems, and mix heads use only the highest quality components and materials.

No part, device, or piece of equipment comes off the shelf. Each is manufactured according to your specifications and designed to support your production goals — both immediately and far into the future. Linden Polyurethane backs the performance of all our offerings with best-in-class service and support, and we can validate ongoing production, conduct feasibility trials, or conduct testing for short-run production in our 7,000-square-foot testing and production facility.

Linden Polyurethane is here to support your success, no matter your production goals, equipment needs, or application standards.