Why the Healthcare Industry Relies on Medical Grade Polyurethane

Polyurethane is one of the most flexible, adaptable, and customizable materials in use in countless applications and markets today. From being used in the military for numerous defense applications due to its strength and affordability to serving as a structural component in the construction industry due to its rigidity and sound absorption properties, there’s no other material like polyurethane. The same goes for healthcare and pharmaceutical, where medical grade polyurethane is used for countless applications.

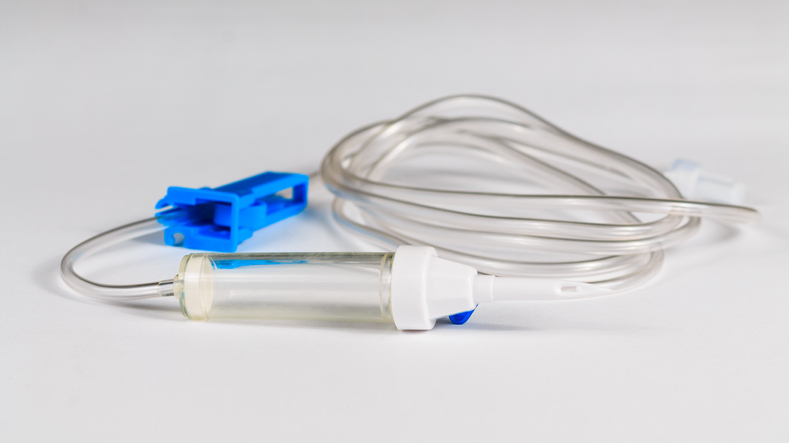

The widespread use of medical grade polyurethane is due to its exceptional biocompatibility, meaning that they interface with living tissue and fluids without producing a toxic or immunological response. Because of this, polyurethane is a common component in numerous types of medical devices that include in-dwelling catheters, general-purpose tubing, wound dressings, short-term implants, dialysis devices, aortic balloon pumps, and artificial heart insulation. Additional medical applications for polyurethane-based devices include hospital bedding, and surgical drapes.

Medical grade polyurethane is ideal for other applications that require high strength, flexibility, tear and abrasion resistance, and processing versatility. This is because many of the applications outlined above can rub in medical environments and are subject to frequent bending and handling. Polyurethanes can be engineered to be softer and more comfortable. This is important in applications where the material may be in contact or even located inside of a patient.

Medical grade polyurethane is indeed an ideal application for the healthcare industry, but achieving these properties isn’t immediate. Proper processing equipment and even testing are needed to ensure that the material will perform as needed in the application it’s being developed for. Let’s explore several areas that are critical to the success of a healthcare-focused polyurethane formulation.

3 Factors for a Successful Medical Grade Polyurethane Formulation

1. Validation of Material and Equipment

The performance of medical grade polyurethane in the healthcare industry is essential. There is no room for error, and the right material blend must be guaranteed for products to pass extreme testing standards and be approved for use in healthcare environments. Beyond in-house testing, a polyurethane testing lab should be utilized to validate both the polyurethane blend itself as well as the equipment being used to manufacture the product.

At Linden Polyurethane, our polyurethane foam testing lab is equipped to help you evaluate your next application need through comprehensive feasibility trials, short-run production testing, and ongoing production evaluation. Opportunities for improvements are shared via in-depth testing results, and as an ISO 9001 certified facility, all testing is completed with the utmost accuracy and reliability. Connect with us to learn more about our polyurethane testing lab and to schedule your own test run.

2. Identification of Ideal-State Equipment

The production environment for medical grade polyurethane devices and components consists of numerous pieces of equipment working in unison to achieve the material properties needed. Each piece of equipment plays a meaningful, performance-impacting role in material output. While your production environment likely consists of some of these systems, the synergy that can be achieved through combination is worth consideration. Companies involved in working with medical grade polyurethane should consider:

- Chemical metering systems for precision and control during production

- Polyurethane mix heads for mixing accuracy and proper shot size

- Gas infusion systems for waste reduction and performance improvement

- Bulk storage and blending systems for greater efficiency and cost savings

- Pentane-supporting systems for environmentally friendly applications

Linden Polyurethane offers a full line of highly customized and engineered polyurethane processing equipment. Explore our portfolio of advanced systems here.

3. Expert Service and Support for Continued Performance

While the ideal production equipment will help you achieve the material properties you’re looking for in medical grade polyurethane, keeping that equipment maintained and operating at peak performance will be essential to ongoing success. That’s why it’s important to have a reliable service and support partner who will be there for your organization whenever equipment needs repair, calibration, replacement, or some other form of service.

At Linden Polyurethane, our repair capabilities and warranty program are second to none. We believe that your investment in polyurethane processing equipment deserves to be protected and supported. That’s why we service our machines and even those of our competitors. Should a situation arise when you need repair or support, our 24-hour service team will be available to address any of your needs. We offer expert technicians with decades of experience, and we are a Bosch Rexroth AG-approved repair facility with an ISO 9001 certification for quality management.

Whether we’re rebuilding a pump or dispatching a field technician to provide on-site support, our team is ready to help. Discover our repair and service offerings here.

Work with the Medical Grade Polyurethane Experts

We understand the critical nature of your products as well as the extreme standards to which your organization is held in order to participate in this industry. That’s why we’ll work with you to ensure your pharmaceutical or healthcare device application is a success. As a complete solutions provider, we offer the testing services, polyurethane processing equipment, and repair and warranty support your organization needs for success. We’ve been working with organizations supporting the healthcare industry since we were founded in 1985, and we’re ready to put that experience to work for your business.

Ready to put our medical grade polyurethane expertise to the test? Connect with us today to learn more and to request a quote.