30

Nov 21Polyurethane Foam Dispensing Equipment Applications Come In Many Forms

- November 30, 2021

Increase the Versatility of Your Material with Critical Equipment

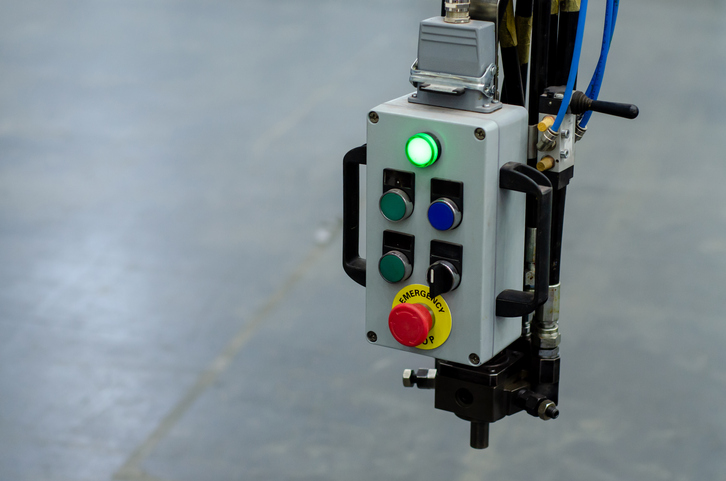

Polyurethane foam dispensing equipment is essential in maximizing the versatility and adaptability of polyurethane as a material that can be designed to service nearly any purpose.

Read more

25

Oct 21Polyurethane Rigid Foam: What Goes Into Making It

- October 25, 2021

Enhance and Tailor Your Capabilities and Capacity

Polyurethane rigid foam, despite its moniker, isn’t limited in scope to the number of industries in which it has become essential.

Read more

21

Sep 21How Chemical Blending Equipment Supports Your Success

- September 21, 2021

Enhance and Tailor Your Capabilities and Capacity

Given the nature of the material, it should be no surprise that chemical blending equipment is an essential component of your success in the manufacturing of polyurethane.

Read more

31

Aug 21Polyurethane Safety: 3 Ways to Protect People & Facilities

- August 31, 2021

Utilize Key Solutions to Alleviate Manufacturing Risk

Polyurethane safety is a primary concern for all manufacturers of the versatile material. Needed and used more than ever across virtually every industry in a variety of forms, polyurethane needs to be produced at a high level, in an efficient fashion, and with the needed precautions to avoid risk to the workers and facilities that handle the material every day.

Read more

30

Jul 213 Benefits of Polyurethane Foam Testing

- July 30, 2021

Validate, Improve, and Analyze with Testing Services

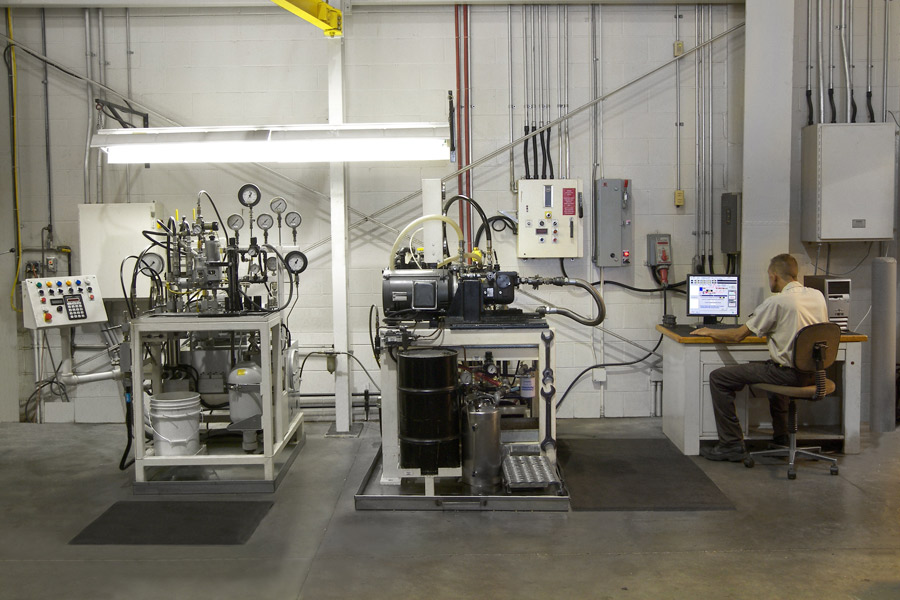

Polyurethane foam testing is essential in ensuring the versatile material meets the demands of the many products and applications, which rely on it each day.

Read more

22

Jun 21Polyurethane Repair: How to Protect Your Investment

- June 22, 2021

Keep Running with Repair, Rebuild, and Replacement Services

With the titanic size of the market, it makes sense for any polyurethane manufacturer, producer, or fabricator to be aware of and employ polyurethane repair services in order to stay up-to-speed with ever-increasing production demands.

Read more

21

May 21Gas Infusion: What It Is and How It Works

- May 21, 2021

Get More from Your Polyurethane Mixtures

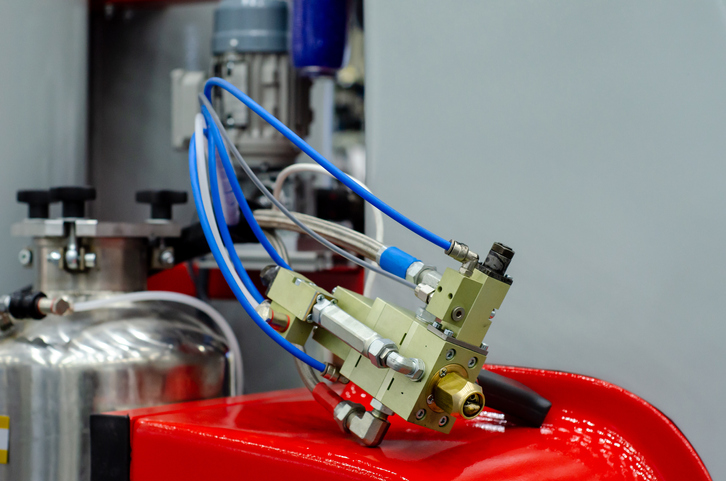

In the polyurethane foam production industry, gas infusion, or gas nucleation, refers to the process of dissolving and distributing a gas into a polyurethane mixture.

Read more

23

Apr 21Achieving Flexible Polyurethane Foam

- April 23, 2021

Proactive Solutions Needed for Flexible Polyurethane Foam

Flexible polyurethane foam (FPF) is nearly ubiquitous in its use across a wide swath of consumer products. As a polymer produced from the reaction of polyols and isocyanates, FPF is characterized by a cellular structure that allows for some degree of compression and resilience while also providing a cushioning effect.

22

Mar 21Polyurethane Services: The Importance of Being Proactive

- March 22, 2021

Being Proactive Matters More Than Ever in Today’s Dynamic Production Environments

With the pandemic came overwhelming uncertainty for many industries, with manufacturing carrying a great deal of it. Innumerable amounts of research have been done on its short- and long-term effects, but it’s clear that even essential operations saw significant upstream and downstream difficulties as suppliers and customers alike were forced to slow down — and in many cases, shut down.

10

Feb 21Polyurethane Foam Spray: Ideal Equipment Considerations

- February 10, 2021

High-Viscosity Spray is Used in Multiple Industries Worldwide

Polyurethane is one of the most flexible materials in today’s market, with countless applications relying on it for performance and extensive customization options. One of the most common multi-industry uses is in polyurethane foam spray. Unlike other applications, spray polyurethane is often high in viscosity and high in temperature — requiring specialized equipment to mix and distribute it.