10

Feb 21Polyurethane Foam Spray: Ideal Equipment Considerations

- February 10, 2021

High-Viscosity Spray is Used in Multiple Industries Worldwide

Polyurethane is one of the most flexible materials in today’s market, with countless applications relying on it for performance and extensive customization options. One of the most common multi-industry uses is in polyurethane foam spray. Unlike other applications, spray polyurethane is often high in viscosity and high in temperature — requiring specialized equipment to mix and distribute it.

27

Jan 21Polyurethane Storage: Savings, Safety, Efficiency & More

- January 27, 2021

Put Your Business in a Strong Position to Meet Demand

The new year is here, but unfortunately, the pandemic rages on. While organizations around the world have been able to resume some semblance of normal operations and planning, there remains the possibility of another shift in demand — requiring you to accelerate production to meet your customers’ needs. And should you find yourself in this situation, the last thing you need to be worrying about is polyurethane storage.

16

Dec 20Custom Chemical Mixing: Improve the Bottom Line Via Material Performance

- December 16, 2020

The New Year is Coming — How Will You Improve Your Production Process?

It’s no secret that 2020 has been a challenging year for manufacturers. Regardless of industry, companies around the world have had to tackle new complexities and roadblocks as a result of the pandemic, tariff challenges, and the subsequent supply and logistics hurdles. But from these challenges have come new ways of thinking, innovative new processes, and solutions designed to help companies get back on track — and stay on it.

18

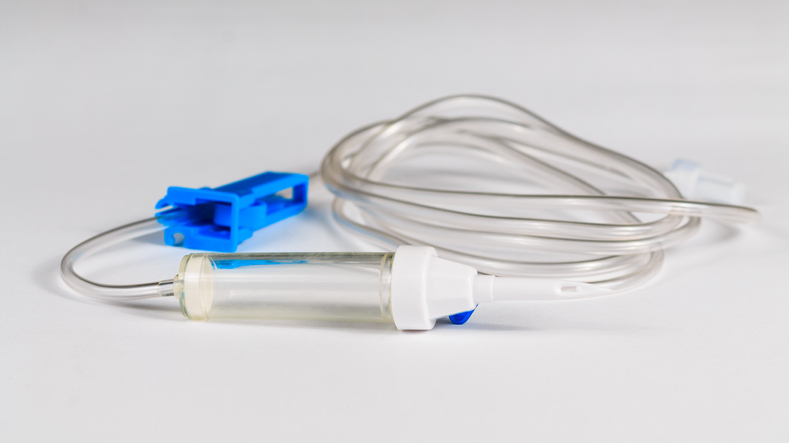

Nov 20Medical Grade Polyurethane: Considerations for Healthy Production

- November 18, 2020

Why the Healthcare Industry Relies on Medical Grade Polyurethane

Polyurethane is one of the most flexible, adaptable, and customizable materials in use in countless applications and markets today. From being used in the military for numerous defense applications due to its strength and affordability to serving as a structural component in the construction industry due to its rigidity and sound absorption properties, there’s no other material like polyurethane. The same goes for healthcare and pharmaceutical, where medical grade polyurethane is used for countless applications.Read more

23

Oct 20Military Grade Foam: Creating Material That Performs Under Pressure

- October 23, 2020

Military Grade Foam is Used in Countless Defense Applications

With Veterans Day around the corner, we wanted to take this opportunity to thank veterans for their service. Your time, energy, and sacrifices are deeply appreciated, and we’re grateful to you for all that you do to keep our nation safe. We also wanted to take the opportunity to share ways that our equipment plays an important part in numerous military grade foam applications.

25

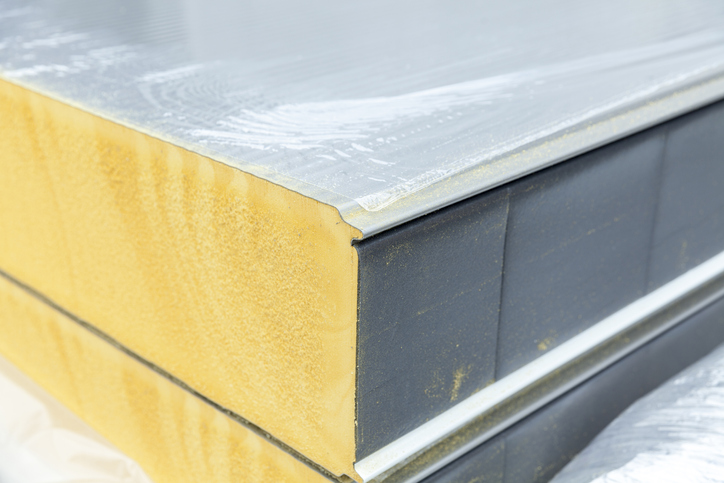

Sep 20The Key to Superior Industrial Strength Foam

- September 25, 2020

Industrial Strength Foam Goes Beyond Industrial Applications

Industrial strength foam isn’t restricted to one or two industries — it’s a common part of multiple industries worldwide. Countless products rely on rigid polyurethane foam as part of their design in order to perform under varying conditions.

27

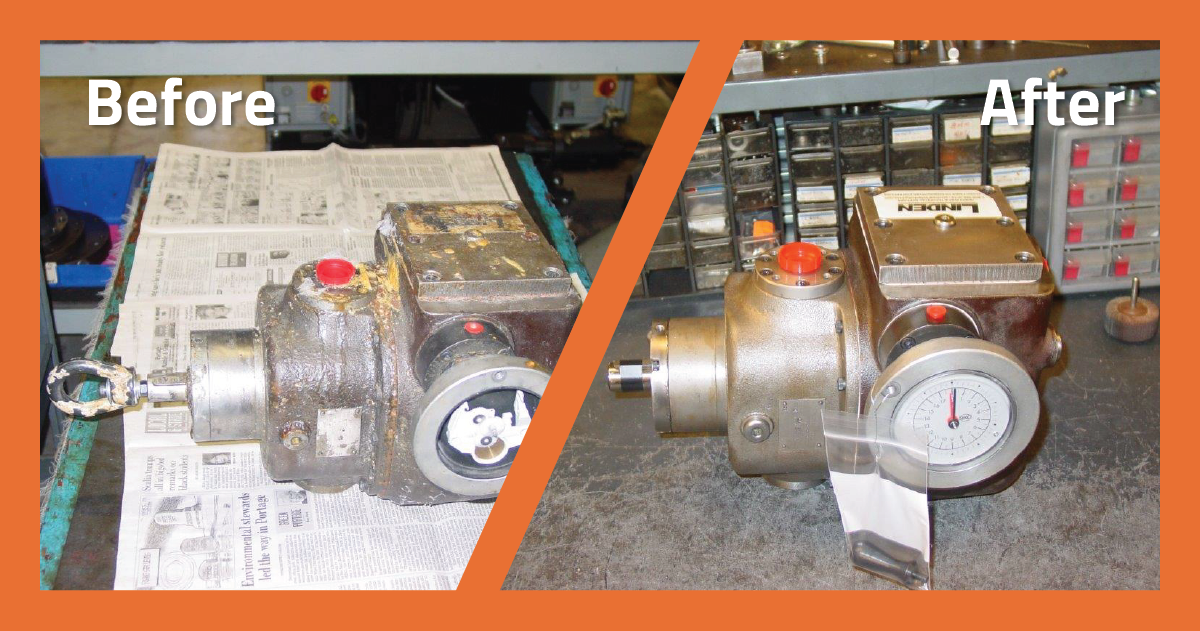

Aug 20The Key to Repairing & Rebuilding Polyurethane Pumps

- August 27, 2020

You Already Know What Your Polyurethane Pumps Can Achieve

When you made the decision to invest in a particular polyurethane pump, you knew what it would be capable of and how it would benefit your production. Over time, you and your team came to realize those benefits. But as time wore on, and the wear on your pumps did as well, their performance and condition likely began to take a dip. Perhaps material was getting stuck, or perhaps corrosion or other negative effects became more apparent.

15

Jul 20Polyurethane Metering Systems: Customization is the Key

- July 15, 2020

Polyurethane Metering Systems are the Heart of Every Production Environment

As the regulation and flow system between material storage and the mix head that disperses that material, the success of every polyurethane application centers on the performance and reliability of these machines. Because these systems play such an important role in your facilities and production chain, it’s critical that they be precisely configured to your needs.

22

Jun 20Ensure Application Success with Polyurethane Testing

- June 22, 2020

Why 2-Step Polyurethane Testing is So Critical for Application Success

Across the world, polyurethane material is in use in countless products and applications that businesses and consumers need and rely on every day. In each situation, the polyurethane mixture used to create the products must be developed to meet the end product performance characteristics. Chemical suppliers such as Dow, Covestro, and BASF engineer these formulations to address both external pressures from the elements like temperature, moisture, and heat and internal pressure such as cellular structure, composition, any gas nucleation used, and so on. In order to achieve success in these applications, the first step of polyurethane testing is dependent on the chemical suppliers.

19

May 20The World is Starting Up Again — How Will Your Equipment Fare?

The stay-at-a-home orders are beginning to lift and people are slowly returning to their places of work. Throughout that time, the polyurethane equipment that many companies rely on for their production has sat dormant, or depending on your business, perhaps with a reduced number of cells in operation. As a result, you may find that equipment needs to be tuned, adjusted, or even repaired due to its inactivity.