Being Proactive Matters More Than Ever in Today’s Dynamic Production Environments

With the pandemic came overwhelming uncertainty for many industries, with manufacturing carrying a great deal of it. Innumerable amounts of research have been done on its short- and long-term effects, but it’s clear that even essential operations saw significant upstream and downstream difficulties as suppliers and customers alike were forced to slow down — and in many cases, shut down.

As a result, understanding what to expect in the weeks and months ahead — even now as companies have long since resumed operations and cases are trending downward — has become challenging. This has made it difficult to know the next best step. For companies providing manufacturing services for industries like aerospace, automotive, household and consumer goods, construction, medical, and even military, it has made polyurethane services all the more critical.

Obtaining these services sooner rather than later (and in some cases taking advantage of them consistently) ensures you’re able to stay ahead of the curve in terms of planning for and meeting demand, maintaining high levels of productivity and uptime, driving down excess costs, and other important production environment metrics. Doing so also ensures that you’re able to identify roadblocks ahead of time, address any issues more proactively before they become significant problems, find opportunities for cost/time savings, and continue meeting your production goals and keeping your customers satisfied.

Here, we’ll explore a few of the vital polyurethane services your organization should consider in order to realize these advantages despite ongoing complexity and uncertainty.

Four Polyurethane Services for Maximum Productivity

1. Mix Head Testing

You already know how essential the mix head is to your production process. Bringing together the various chemicals being used in your application, an effective mix head is not only one of the final production phases but is also one of the most critical. But different chemicals and applications require specific mix heads in order to be successful. Some chemicals need to impinge at certain angles to achieve the best possible mixture prior to distribution, whereas others may work perfectly with a straight-style mix head.

What matters most here is identifying the proper mix head for your unique application and goals. While it may seem that this would just be part of the sales process, validation of the mix head can save significant time and resources — particularly for new applications within the business or when specific dispensing methods may be needed (such as pouring vs. spraying). While it’s unlikely that you would inadvertently purchase the wrong mix head for your application, it would be far more advantageous to test a variety of mix heads that experts know are suitable for specific chemicals and applications ahead of time. This way, you’ll know whether the mix head will function and whether it’ll excel over other models.

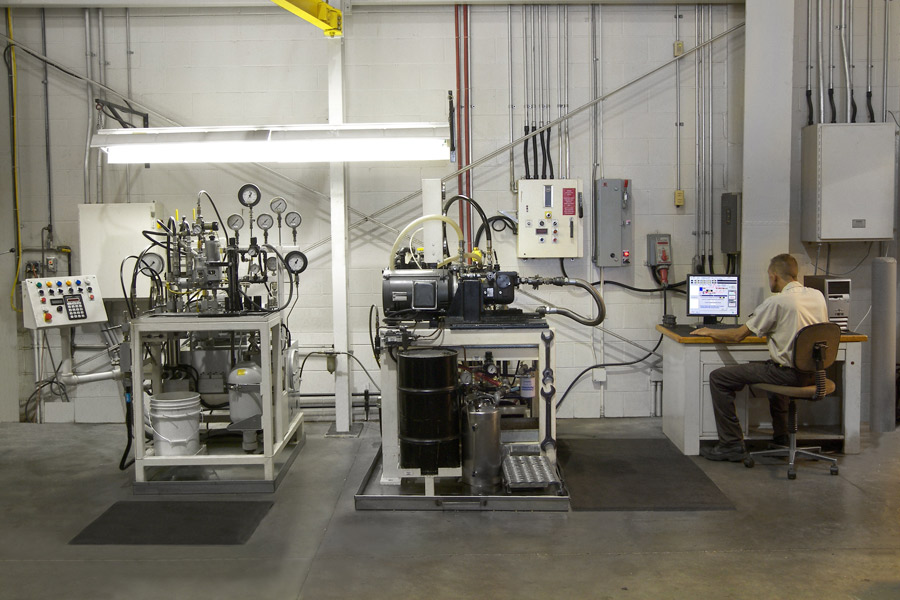

The Linden difference: We provide a full range of mix heads for you to test as part of our polyurethane test lab capabilities. Learn more about the equipment available for testing.

2. Equipment & Material Validation

Closely related to mix head testing is using a testing lab to validate other equipment types. This is an essential part of the polyurethane services list as it allows you to validate and experience different equipment types before purchase or prior to beginning production of a new product. Metering machines, pumps, spray machines, Pentane equipment, and blending systems are all part of the apparatus that makes up an efficient polyurethane production environment, so taking advantage of these polyurethane services ensures you’re making the right investment and maximizing productivity from the start.

Additionally, such testing labs can assess the viability of different chemical formulations for use within these different equipment types. If you have a low-pressure application that requires a chemical mixture with greater viscosity, it’ll be important to understand how that material will move through the various systems you’ll be using. Combined with equipment validation, testing materials is a great way to proactively evaluate the application as a whole and ensure no material is wasted, the equipment will maintain peak performance, and you can realize your overall production goals.

The Linden difference: Virtually every type of machine we make can be tested as part of our polyurethane services and test lab capabilities. Learn more about our lab here.

3. Rebuilding & Refurbishing

You already know that polyurethane processing equipment is a significant investment. You also expect to get the most out of that investment — not just in the short term but also for years to come. While there are different equipment grades available in a range of costs, it’s inevitable that it will eventually begin to wear, causing reduced performance and yield, or that it will experience an unexpected failure of some kind.

Fortunately, many polyurethane components can be refurbished or rebuilt — extending their lifespan and returning their performance to like-new levels. This is a significant advantage cost-wise when compared to simply buying another system or part. In only a matter of days or weeks depending on urgency and complexity, your pump, mix head, or other polyurethane processing system can be restored.

The Liden difference: In addition to our certified team, Liden also repairs and restores equipment built by our competitors, providing you with a go-to solution for all of your equipment repair needs. Learn more about our new Zip-It & Ship-It program here.

4. Bulk Storage & Blending

While not a specific polyurethane service, bulk storage and blending solutions provide your business with precisely what they sound like — high-capacity chemical storage and material blending equipment. These are early-stage process solutions that take the traditional methods of storing polyurethane in barrels and totes out of the picture entirely, replacing them with more efficient, cost-effective, safer, and more environmentally friendly tanks. A variety of sizes are available depending on your production goals.

Using these systems allows you to maintain a more continuous and streamlined production environment. They eliminate the need for workers to manually move barrels and totes from one location to another (which can risk spills and injuries). On the bulk blending side, they allow chemicals to be correctly mixed and metered into the production chain earlier, removing the need for this to happen mid-cycle.

The Linden difference: Linden Polyurethane manufactures, customizes, installs, and supports various bulk storage and blending solutions. Learn more about them here.

Get the Right Polyurethane Services for Your Goals

Since 1985, Linden Polyurethane has been helping companies in multiple industries around the world not only get the right equipment for their needs but support their production with polyurethane services that increase efficiency, throughput, and more.

Ready to take your production environment to the next level? Contact us today.