Industrial Strength Foam Goes Beyond Industrial Applications

Industrial strength foam isn’t restricted to one or two industries — it’s a common part of multiple industries worldwide. Countless products rely on rigid polyurethane foam as part of their design in order to perform under varying conditions.

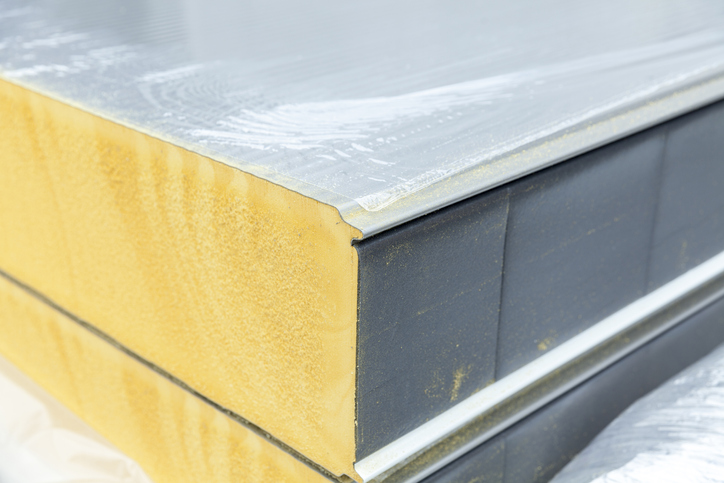

For example, in the construction industry, industrial strength foam is critical to the integrity of commercial and residential structures. It helps to provide high levels of insulation for walls, doors, and windows as well as noise reduction, which is particularly useful for commercial properties that see high levels of traffic or have loud ambient noise. Without polyurethane, builders would have to use multiple — and often more expensive — materials, and even then, they may not be able to achieve the same properties.

In the consumer products and sporting goods industries, industrial strength foam serves a number of distinct purposes. It provides thermal insulation for appliances and can also be used for coatings to protect surfaces from rust and heat damage over time. For sporting goods, it provides impact resistance and durability for protective equipment and helps other athletic items maintain their performance under extremely rigorous conditions.

These are only a few examples of industries and applications where industrial strength foam is critical to success. With these markets anticipated to grow over the next several years, now is the time to invest in the systems and capabilities you need to deliver higher levels of performance and better compete on a national and even global scale.

But what is needed to ensure your polyurethane foam is up to par? Let’s explore the various components of an industrial strength foam production environment and how each of these makes a respective contribution to success.

The Elements of a Strong Industrial Strength Foam Production Environment

A High-Performing Mix Head

The mix head is the most important part of production despite being one of the last pieces of equipment used in the process. This is because the manner in which material is mixed in the chamber impacts its performance. For example, L-style mix heads combine material at a 90° angle, ensuring it blends thoroughly, slows the material down, and allows distribution with the ideal properties preserved.

The ideal mix head will be able to perform long-term and, if something were to happen, restoring it should be a simple and efficient process. At Linden Polyurethane, for example, our mix heads are not only engineered to the highest quality standards, but our team also provides rapid repair and rebuilding services for many brands — even those of our competitors. Once repaired or rebuilt, our certified team performs testing on the mix head to ensure it will resume its high-performance role within your production environment.

The Chemical Metering System

Polyurethane metering systems are the heart of the industrial strength foam production environment. Not only are they at the center of the process, but they’re also critical to achieving the right material balance and distribution rate for your application.

For example, high pressure metering systems are ideal in applications that require high output as well as low-output for open or closed mold pourings or spray. Achieving success in these instances requires properly designed and engineered systems tailored to the application. And when it comes to industrial strength foam, only the best chemical metering system will do.

For applications where lower volumes, higher or varying viscosities, or other non-polyurethane chemicals are needed, low-pressure metering systems are ideal. These highly engineered systems must ensure proper material flow for multiple materials, ensuring effective treatment prior to their distribution. Applications demanding this level of performance include aerospace, automotive, and construction.

Cost-Saving Bulk Solutions

With all of the industries we’ve discussed thus far expected to grow over the next several years, production needs are bound to start ramping up — if they haven’t already. Rather than deal with expensive, time-consuming, wasteful, and unsafe drums and barrels, you can achieve greater efficiency and cost savings in using bulk storage and blending solutions.

On the bulk storage side, this means replacing all those drums with larger systems capable of storing anywhere from 2,000 to 25,000 gallons of material in one or more built-in containers. These can be integrated into your production process as well, allowing you to move material into a blending system or the next phase of production. Not only do these bulk storage systems support your industrial strength foam production goals but they also significantly improve the bottom line. They can be custom designed to be refilled by truck deliveries and even by railcar for larger quantities.

While having more material on hand provides immediate cost savings upfront, bulk blending solutions provide long-term advantages in the form of superior end-product performance. The last thing you want is to have your industrial strength foam underperforming. Bulk blending improves material performance at the molecular level, infusing gases such as carbon dioxide or nitrogen into the polyurethane mixture. These gases can help to improve cell structure, sound absorption properties, material flow, and more — ultimately helping to create a better product while reducing costs associated with waste.

A Reliable Repair Partner

Last but not least is working with a company that can help you maintain the highest levels of productivity through equipment repair, rebuilding, testing, and other forms of service. Much of the equipment in use today is manufactured by different companies throughout the world. Shipping parts to other countries or relying on potentially costly field service visits from these companies can quickly become overwhelming, but the greatest impact to your business is in downtime.

That’s why it’s so important to work with a local company that not only provides faster service and reduced shipping costs but also is capable of servicing many different brands and types of equipment. This ensures you’re able to get back up and running faster than if you had to send equipment abroad for service.

Work with a Strong Partner for Industrial Strength Foam

Linden Polyurethane is a leading manufacturer of custom polyurethane processing equipment for industries around the world. Our high-performance mix heads, metering systems, spray equipment, and bulk storage/blending solutions are all custom-engineered to meet your most demanding specifications. Our equipment consistently delivers the performance that companies need to meet their production goals, and it’s all backed up by best-in-class service and support.

If you’ve been looking for a reliable partner to help you achieve your goals, our team is here to assist. We’ll help you identify the right equipment through our advanced testing lab and will be there to support you for the life of your equipment.