Linden L-Style Polyurethane Foam Mix Heads

As a global leader in the polyurethane processing and equipment industry, Linden Polyurethane offers a number of polyurethane foam mix head options to help you achieve your production goals. Our polyurethane foam mix heads represent the most advanced and highly engineering options available on the market today — ensuring that no matter the application, you’ll be able to achieve the results you’re looking for with uncompromising accuracy and reliability.

Our L-style polyurethane foam mix head are built using unique alloys, precise machining techniques, and specialized surface treatments. Every mix head is researched, engineered, and tested by our expert in-house team.

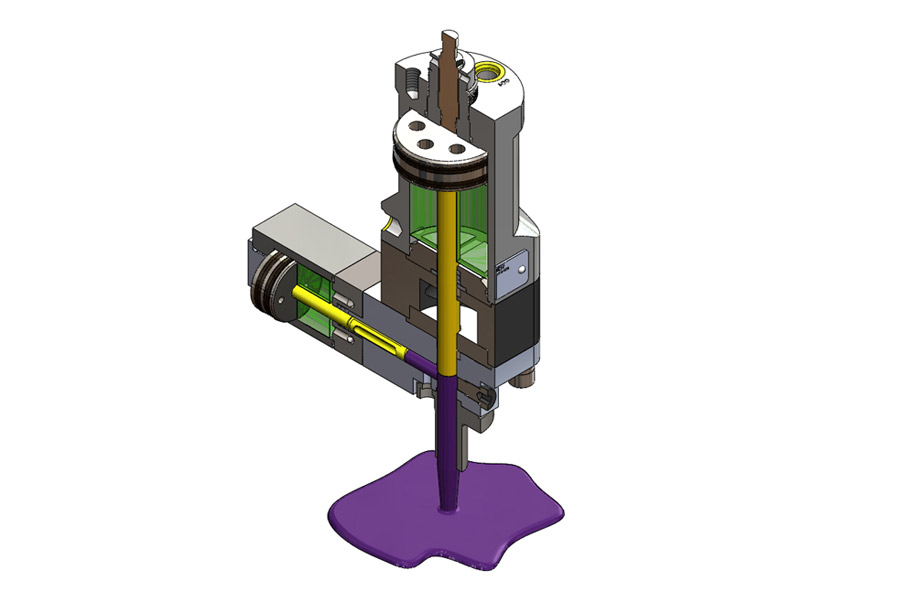

How the L-Style Polyurethane Foam Mix Head Works

The L-style polyurethane mix head features two mixing chambers perpendicular to each other. Materials counter-impinge in a small horizontal chamber and are then forced into a larger chamber from where they are distributed. This 90º change results in further improved mixing and slows material velocity and ultimately ensuring laminar flow.

Available L-Style Polyurethane Foam Mix Heads

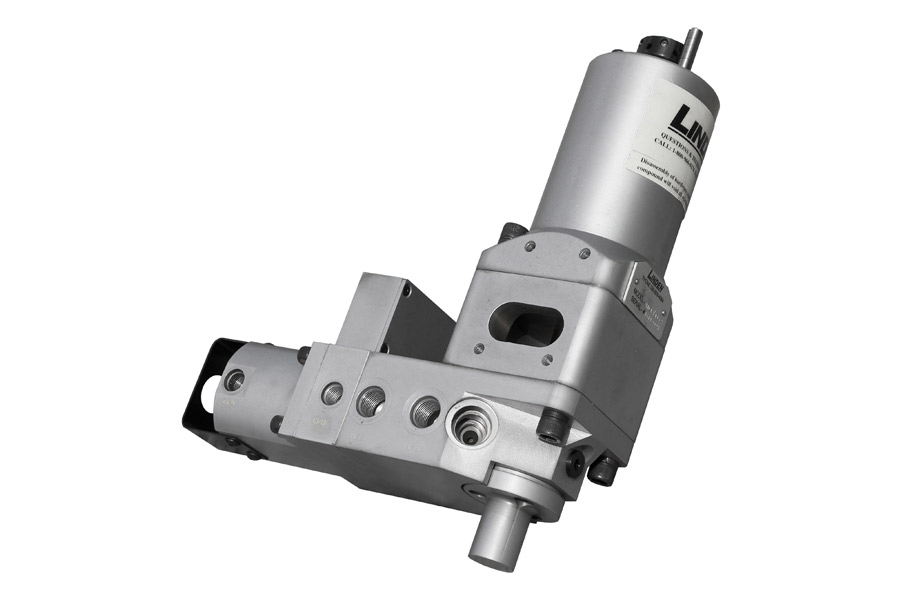

Linden L-Style Mix Head

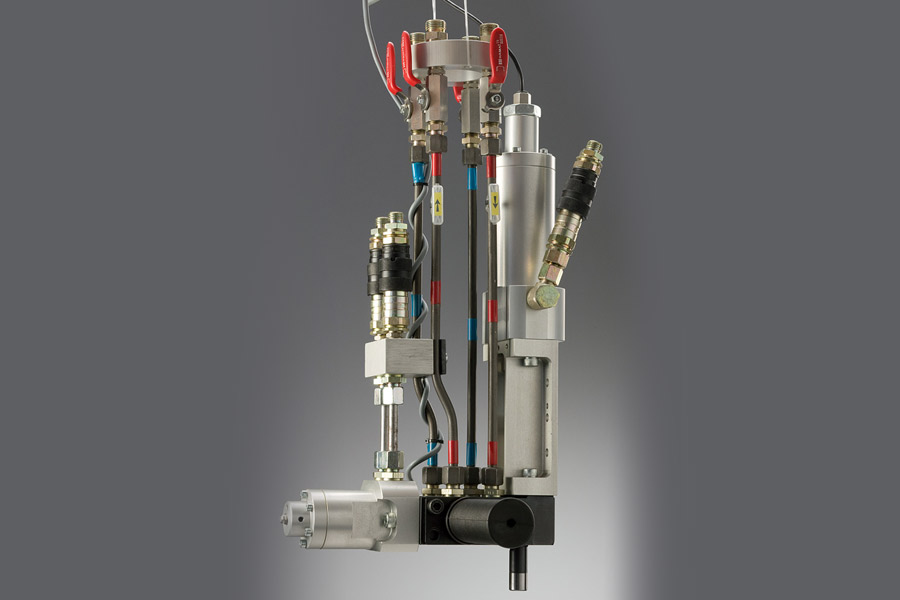

Linden Polyurethane offers L-style polyurethane foam mix heads in three models with varying stream types, mix ratios, and output levels. Models are available in 2-stream, 3-stream, and duplex variations to support your production goals with our industry-leading warranty program that covers up to 1,000,000 shots and up to 30,000 shots for abrasive materials.

- Available in patented 120º and 180º impingement models

- Ideal for molded, flexible, and rigid foams as well as filled systems, RIM, RRIM, and SRIM

- Mix heads self-clean via a complex system of hydraulic rods

- Splash-free pouring ensures impeccable surface performance

- Electronic shot counter helps indicate when maintenance is needed

- Supported by a best-in-class warranty and repair program

- Features a compact and user-friendly design

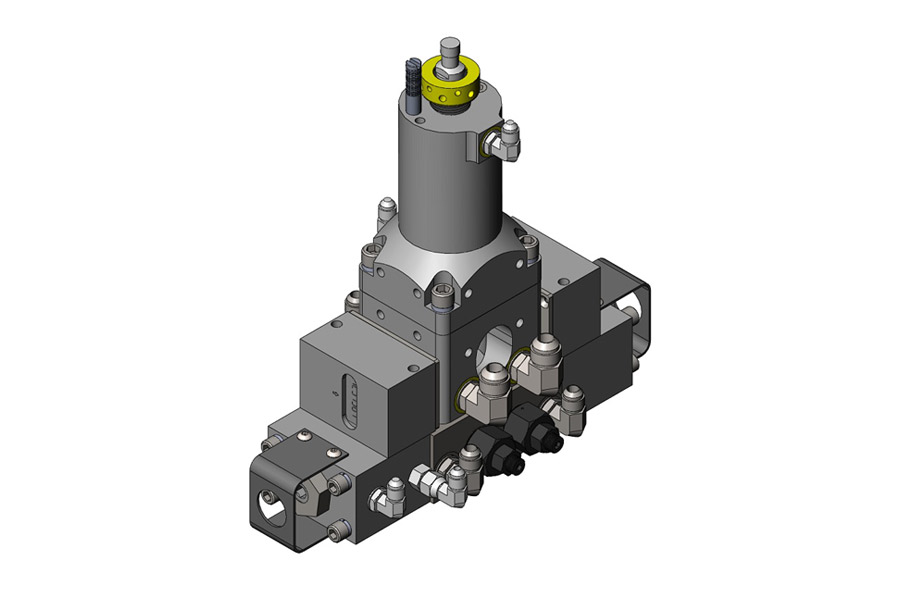

GP600 L-Style Mix Head

The Linden-Isotherm GP 600™ high-pressure polyurethane foam mix head is ideal for applications requiring a smaller output. Material is mixed via high-pressure impingement and can be distributed splash-free with laminar flow into open molds or injected into closed molds.

- Shot sizes as small as 3 grams with incredible repeat accuracy

- Mechanically self-cleaning — no need for solvents or flushing

- Metal-to-metal sealing ensures a high level of reliability

- Mix ratios ranging from 4:1 to 1:4 using different mix chambers

- Modular design for further customization and performance optimization

- Supported by a best-in-class warranty and repair program

Note that due to the unique nature of this polyurethane foam mix head style, the GP 600™ is only available as a direct replacement for an existing mix head or with a complete Isotherm system.

Ready to Get Started?

Contact us today to learn more about our polyurethane foam mix head options.

| L-Head Models | Ratio | ||||

|---|---|---|---|---|---|

| (2-Stream) Model Code | (3-Stream) Model Code | Open/Closed Pour | 1:1 | 2:1 | 3:1 |

| MHL 3/5-2-38-180 | N/A | Closed Pour | N/A | N/A | N/A |

| Open Pour | 15-50 | 20-38 | N/A | ||

| MHL 5/8-2-38-180 | N/A | Closed Pour | 25-110 | 37-82 | 50-74 |

| Open Pour | 25-82 | 37-62 | 39-50 | ||

| MHL 6/10-2-38-120 | MHL 6/10-3-38-180 | Closed Pour | 60-220 | 90-165 | 120-150 |

| Open Pour | 60-165 | 90-125 | 95-110 | ||

| MHL 8/12-2-38-120 | MHL 8/12-3-38-180 | Closed Pour | 77-292 | 116-242 | 123-223 |

| Open Pour | 77-220 | 116-182 | 123-168 | ||

| MHL 10/14-2-38-120 | MHL 10/14-3-38-180 | Closed Pour | 90-610 | 135-460 | 180-410 |

| Open Pour | 90-460 | 135-345 | 180-310 | ||

| MHL 12/19-2-38-120 | MHL 12/19-3-38-180 | Closed Pour | 160-1050 | 240-790 | 320-700 |

| Open Pour | 160-790 | 240-590 | 320-525 | ||

| MHL 14/20-2-38-120 | N/A | Closed Pour | 300-1275 | 451-1150 | 601-1000 |

| Open Pour | 300-956 | 451-862 | 601-749 | ||

| MHL 16/25-2-48-120 | MHL 16/25-3-48-180 | Closed Pour | 600-2150 | 900-1610 | 1200-1440 |

| Open Pour | 600-1600 | 900-1200 | 950-750 | ||

| Duplex (Double L-Head) Models | Ratio | ||||

|---|---|---|---|---|---|

| Model Code | Open/Closed Pour | 1:1 | 2:1 | 3:1 | |

| MHDL 6/6/10-4-38-120 | Closed Pour | 60-220 | 90-165 | 120-150 | |

| Open Pour | 60-165 | 90-125 | 95-110 | ||

| MHDL 8/8/12-4-38-120 | Closed Pour | 77-292 | 116-242 | 123-223 | |

| Open Pour | 77-220 | 116-182 | 123-168 | ||

| MHDL 10/10/14-4-38-120 | Closed Pour | 90-610 | 135-460 | 180-410 | |

| Open Pour | 90-460 | 135-345 | 180-310 | ||